From the Field: Speed Up Estimating with IntelliBid Assemblies

Article written by: Stephen Carr

In my previous article, I introduced some IntelliBid features, including the database, where the descriptions of about 135,000 electrical components are stored, along with material prices, labor units, catalog numbers and many other attributes. I also introduced Assemblies, but did not discuss just how powerful this feature is in Conest IntelliBid.

Why are assemblies a big deal? They save a tremendous amount of time by allowing an estimator to input many components in the same amount of time it takes to input one component. For instance, a branch conduit assembly may include conduit, couplings, connectors, supports, and wire. Without assemblies, the estimator would have to input five different components. By using an assembly, only one thing needs to be input. That’s a fivefold increase in speed.

What are assemblies?

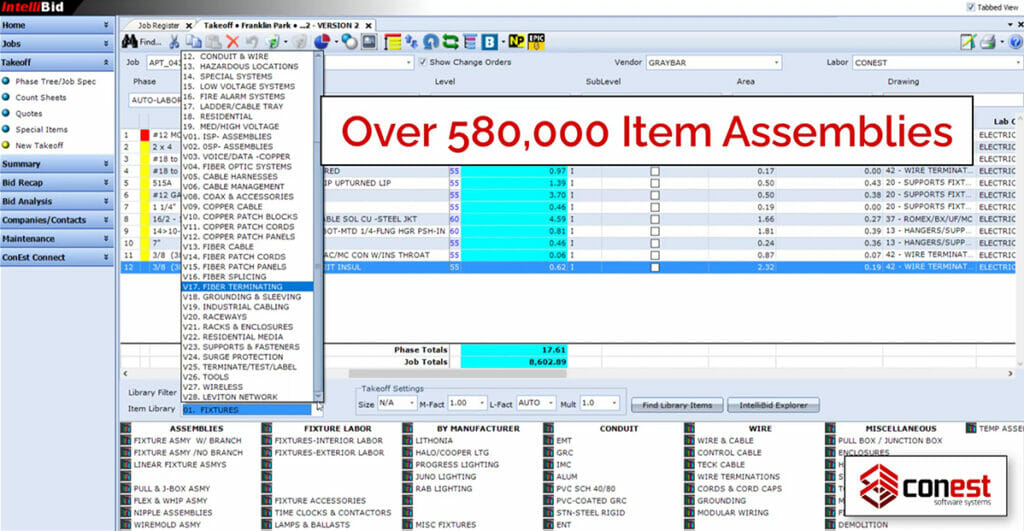

The concept of assemblies in a computer estimating system has been around a long time. The very first computer estimating system I used in 1980 had assemblies. So, what’s the big deal with IntelliBid Assemblies? I call them “super-assemblies.” No, they are not able to leap over tall buildings in a single bound. However, just one IntelliBid Assembly can act as hundreds of normal assemblies. Some of my favorites are the wiring devices with conduit assemblies. Just one assembly may include five different kinds of plates, eight depths of plaster rings, eight options for EMT fittings, several options for supports and the option to include a ground wire. An estimator can select from all of the options during input, or save a large amount of time and clicks by selecting many options before inputting takeoff. For instance, I might preselect stainless steel plates, 5/8” deep plaster rings, steel set screw EMT fittings, my favorite Caddy clip and include a ground wire.

While that’s all well and good, what if I don’t like the assembly? It only gives me 10% extra wire for waste and makeup, and I want 12%. Well, if the assembly is not right for you, simply change it. Before IntelliBid, I never had the ability to change an existing assembly. Even better, one can copy and paste an existing assembly and modify the copy: leaving the original intact. Better yet, you can create your own assemblies from scratch. What if a component that you need is not in the database. You can add it. It only takes a minute to add the description and labor unit. If you want automatic price updates, you can simply copy the UPC from your pricing service and paste it into your new item. Awesome!

Watch a segment about IntelliBid’s Items and Assemblies database:

Customizing assemblies to work for you

Now let’s investigate assembly editing a little closer. On the simple side, any component in the database can be added to an assembly. You can set a multiplier and a labor factor. For instance, to add makeup to a wire, set the multiplier to 1.10 for adding ten percent. For “advanced” estimators, you can get under the hood and harness the power of the formulas attached to every component in an assembly. Formulas are a Boolean Logic (also known as Boolean Algebra) construct that tells the system how each component relates to the rest of the assembly. Boolean Logic is complex.

A typical formula looks like this: IF(AX@<=AR@,0,5,FI@*((AX@-AR@)+0.5))

Even though I was taught Boolean Logic in a Digital Logic class, I decided then it was not something in which I wanted to specialize. Seeing formulas like the one shown above reaffirms my decision. I recommend getting assistance from Conest before messing with the formulas. For me, I almost always copy a similar assembly, so I don’t need to try changing the formulas. Of course, if you do not need the power of formulas, you can just input the formula F0, which causes the program to ask for a quantity every time.

Even though IntelliBid Assemblies are easy to edit and create, I seldom do. The reason is, there are over 500,000 Assemblies in the program already, and many of those are super-assemblies. I prepare estimates for most types and sizes of work, and rarely have the need to create or edit assemblies. Most often, when I need to create a new assembly, it is unique to the project, so I use the Temporary Assembly feature. This feature could not be easier to use. Input the items you need for the assembly, highlight them on the Audit Trail, right click the highlighted area and select Temporary Assembly. A window pops up allowing you to edit a few things. When you are done editing, which I seldom need to do, hit enter and you have created a Temporary Assembly.

By the way, if you did not read my previous article about IntelliBid’s Interface, The audit trail occupies about half the screen while you are inputting your takeoff. Immediately after entering a takeoff item, it appears on the audit trail, where you can delete, cut, copy, paste and edit the takeoff item, similar to how a spreadsheet works. This is simply one of the most awesome features I have ever seen in an electrical estimating program. It’s right up there with the assembly’s feature.